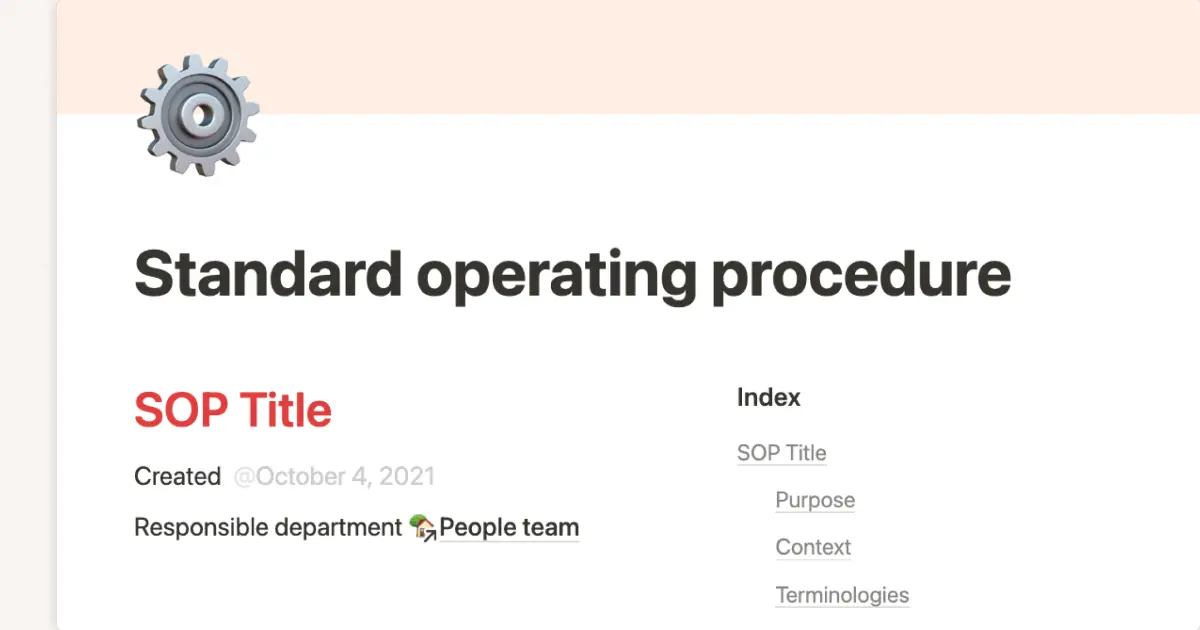

Production Manager SOPs

Sobre este modelo

This template contains a comprehensive set of Standard Operating Procedures (SOPs) designed for a Production Manager. These SOPs cover a wide range of responsibilities, including production planning and scheduling, inventory and material management, workforce allocation and shift planning, machine maintenance and downtime management, and quality control and inspection procedures. Each SOP outlines the purpose, scope, and detailed steps necessary to ensure efficient and effective operations within a manufacturing facility.

The production planning and scheduling SOP focuses on optimizing resource utilization and on-time delivery through careful planning, scheduling, and coordination with other departments. The inventory and material management SOP details the processes for managing raw materials and finished goods to prevent shortages, minimize waste, and ensure a smooth production flow. Workforce allocation and shift planning SOP aims to optimize production efficiency and maintain compliance with labor laws through effective workforce scheduling and task assignment.

The machine maintenance and downtime management SOP provides guidelines for maintaining production machinery to minimize downtime and extend equipment lifespan, including preventive, predictive, and corrective maintenance. The quality control and inspection procedures SOP ensures product quality through systematic inspections, defect prevention, and compliance with industry standards and customer expectations, covering raw materials, in-process production, and finished goods.

Further SOPs address health and safety compliance, incident reporting and investigation, employee training and development, production efficiency and waste reduction, and supplier and vendor management. The health and safety compliance SOP emphasizes maintaining a safe production environment through hazard identification, PPE requirements, and emergency procedures. The incident reporting and investigation SOP outlines the process for reporting, documenting, and investigating workplace incidents to prevent future occurrences.

Finally, the employee training and development SOP focuses on enhancing employee skills and ensuring safety compliance through comprehensive training programs. The production efficiency and waste reduction SOP aims to improve productivity and minimize waste through lean manufacturing principles and process optimization. The supplier and vendor management SOP ensures the timely delivery of quality materials and maintains cost efficiency through effective supplier relationships and procurement processes.