Bread Baker In Manufacturing SOPs

템플릿 설명

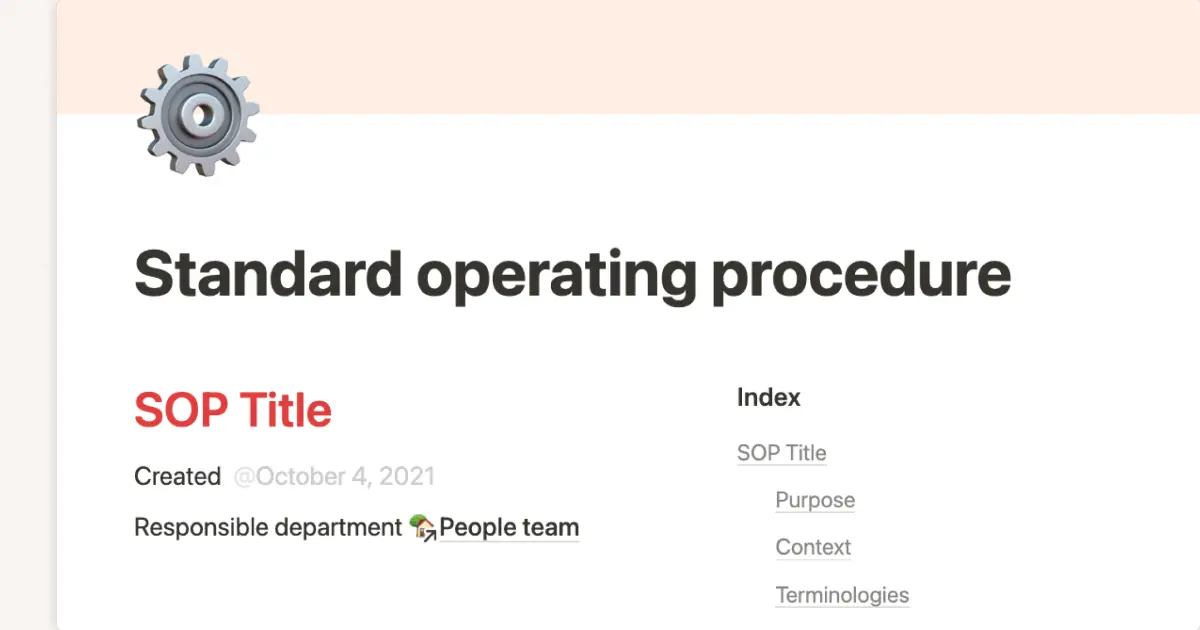

This template contains Standard Operating Procedures (SOPs) for a bread baker in a manufacturing setting. It outlines detailed procedures for every step of the bread-making process, from the initial dough preparation to the final packaging and storage of the finished product. Each SOP is designed to ensure consistency, quality, and safety throughout the manufacturing process.

The first SOP focuses on the dough preparation process, including gathering and measuring ingredients, preparing equipment, mixing the dough, checking dough temperature, fermentation, monitoring fermentation, degassing the dough, and preparing for the next stage. This ensures the dough is correctly made and ready for shaping.

The second SOP details the dough shaping and proofing process, which includes preparing the workspace, dividing the dough, pre-shaping, final shaping, proofing, conducting final checks, and transferring the dough to the baking area. This stage is crucial for achieving the desired texture and appearance of the bread.

The third SOP outlines the baking procedure, including preheating the oven, preparing for loading, loading the oven, monitoring the baking process, checking for doneness, removing the bread from the oven, post-bake cooling, and recording baking data. Proper baking is essential for achieving the correct crust, color, and internal temperature.

The remaining SOPs cover ingredient handling and storage, equipment cleaning and maintenance, final proofing guidelines, packaging procedures, the cooling process, food safety and hygiene guidelines, and workplace safety procedures. These ensure that all aspects of the bread-making process are conducted safely, hygienically, and efficiently.