Laundry Operator SOPs

À propos de ce modèle

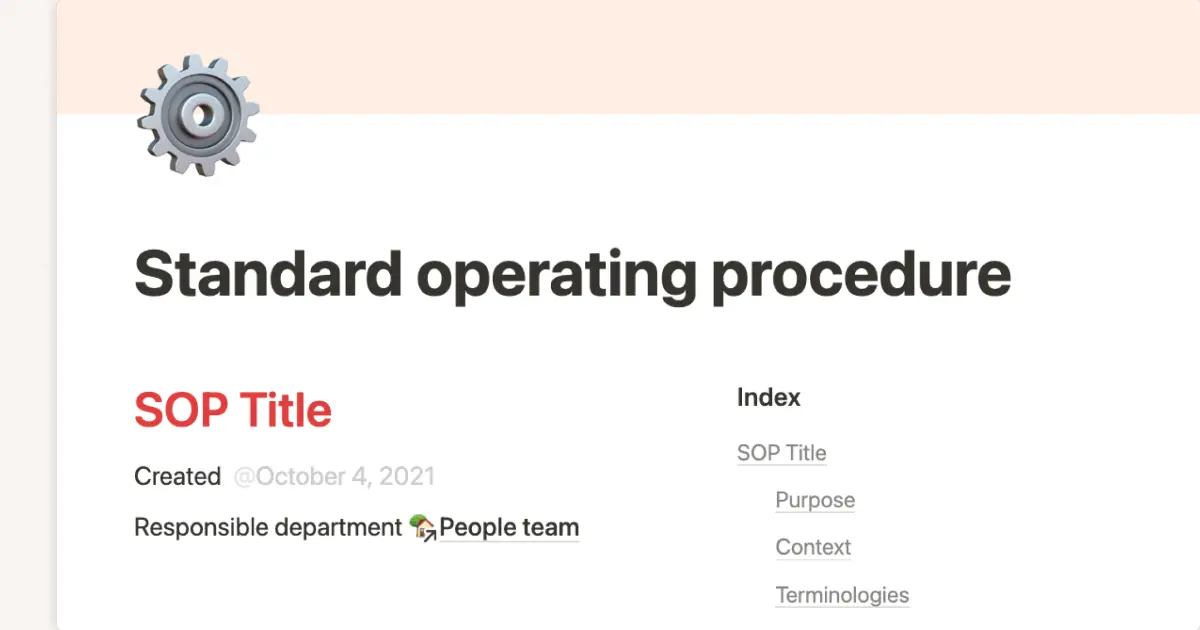

This template contains Standard Operating Procedures (SOPs) for a laundry operation. The first SOP is about sorting laundry for processing, which includes preparing the sorting area, inspecting incoming laundry, sorting by color, fabric type, and soil level, handling contaminated items, tagging special care items, reviewing and finalizing sorting, and maintaining a clean environment. The purpose is to ensure that laundry items are correctly sorted for efficient processing and proper care.

The second SOP is about loading washing machines safely and effectively. It details inspecting the machine, verifying sorted laundry, pre-treating items, loading the machine, adding detergents, selecting the appropriate cycle, starting the machine, monitoring progress, unloading promptly, and cleaning the machine. The purpose is to ensure washing machines are loaded correctly to maximize efficiency and prevent damage to fabrics and equipment.

The third SOP is about handling stains and pre-treatment procedures. It includes preparing the workstation, inspecting laundry for stains, identifying the stain type, testing for colorfastness, applying the pre-treatment solution, agitating the stain, rinsing or blotting the area, setting aside for laundering, reassessing after washing, and cleaning the workstation. The purpose is to effectively identify and treat stains before laundering, ensuring that garments and linens are returned in optimal condition.

The fourth SOP is about folding and packaging clean laundry. It details preparing the folding area, inspecting the laundry, folding according to item type, using folding aids, stacking neatly, packaging items, labeling packages, conducting a final quality check, storing or dispatching items, and maintaining a clean workspace. The purpose is to ensure that clean laundry is neatly folded and appropriately packaged for delivery or storage.

The fifth SOP is about setting up washing machine programs. It includes understanding machine capabilities, inspecting the laundry, selecting the appropriate cycle, setting the temperature, adjusting the spin speed, adding cleaning agents, configuring additional settings, loading the machine, starting the machine, documenting machine usage, and monitoring progress. The purpose is to ensure washing machines are programmed with the correct settings for each load, optimizing cleaning performance while protecting fabric integrity and conserving resources. Other SOPs in the document include operating drying machines efficiently, managing laundry inventory, quality control checks for finished laundry, handling customer complaints and resolutions, and reporting and preventing operational errors.