Manufacturing SOPs

Acerca de esta plantilla

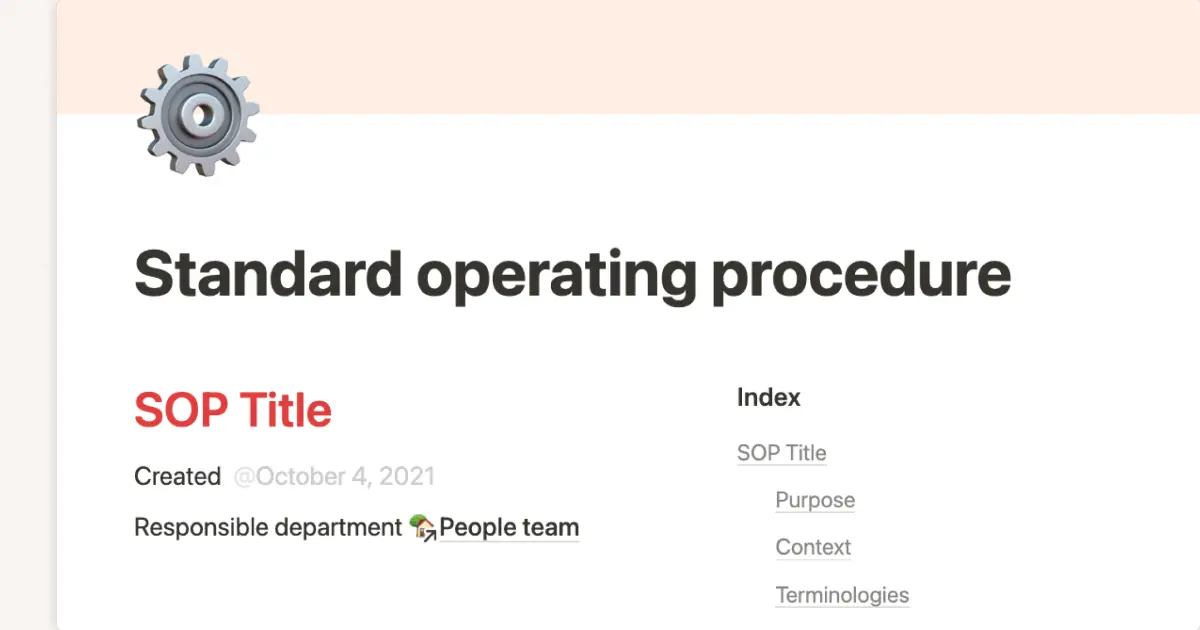

This template contains Standard Operating Procedures (SOPs) for manufacturing. The first SOP focuses on Quality Control, with steps to understand quality standards, establish inspection points, and prepare quality control tools. It also details how to conduct inspections of incoming material, in-process products, and final products, and how to handle non-conforming products.

The second SOP is about Machine Setup and Calibration. It includes reviewing setup requirements, inspecting the machine, and preparing tools and materials. There are also instructions on how to set up, calibrate, and test the machine, as well as how to document the setup and train operators. The third SOP covers Raw Material Inspection, with steps on how to review purchase orders, prepare for and conduct inspections, document results, and handle non-conforming materials. It also includes information on how to communicate with suppliers and conduct audits.

The fourth SOP is on Equipment Maintenance. It outlines how to create a maintenance schedule and perform daily checks. It also includes instructions on how to inspect, calibrate, and clean equipment, as well as how to document activities and respond to failures. SOP 5 covers the Safe Handling of Manufacturing Equipment, with steps on understanding safety guidelines, completing training, and wearing PPE. It also includes information on how to inspect and operate equipment, adhere to emergency procedures, and report incidents.

The sixth SOP is about Handling Non-Conforming Products. It details how to identify, tag, segregate, and document non-conforming products. It also includes steps on root cause analysis, determining disposition, and implementing corrective actions. The seventh SOP covers Changeover Procedures for Multi-Product Lines. It outlines how to schedule changeovers, prepare the new product setup, and shut down equipment safely. It also includes steps on cleaning and inspecting, installing new tooling, updating machine settings, and documenting the changeover. The remaining SOPs cover Managing Inventory in Manufacturing (SOP 8), Communicating with Suppliers (SOP 9), and Emergency Response for Equipment Failures (SOP 10).